What impact does the production process of integral welded flower pot have on the environment?

Release Time : 2024-11-29

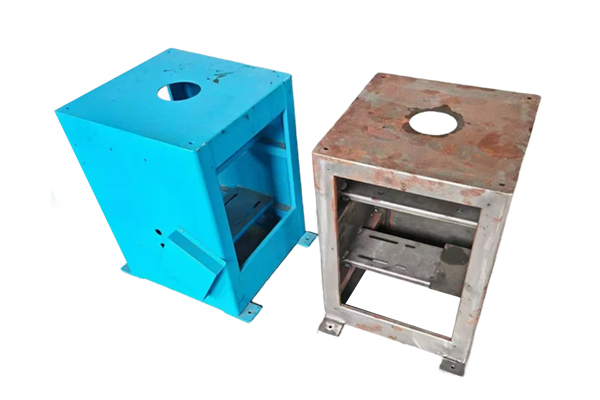

The integral welded flower pot is popular for its durability and unique shape, but its production process has a certain impact on the environment. The waste gas, waste slag and energy consumption generated during the welding process are all environmental issues that cannot be ignored.

In the production process of integral welded flower pot, welding is a key link. However, welding operations are often accompanied by the emission of harmful gases, such as ozone, nitrogen oxides, etc., which pollute the atmospheric environment. At the same time, the waste slag and smoke generated during welding also pose a potential threat to soil and water bodies. In addition, energy consumption in the production process, especially the use of electricity and gas, also exacerbates greenhouse gas emissions.

In order to reduce the carbon footprint in the production process of integral welded flower pot, we can take a series of measures. First, optimize the welding process, improve welding efficiency, and reduce energy consumption and harmful gas emissions. For example, the use of advanced welding equipment and technologies, such as automated welding robots, can significantly improve welding accuracy and efficiency, while reducing errors and pollution caused by human operations.

Secondly, choosing environmentally friendly materials is also the key to reducing carbon footprint. In the production of flower pots, priority should be given to the use of recyclable, degradable or low environmental impact materials. These materials not only have less impact on the environment during the production process, but are also easier to handle and recycle after being discarded.

In addition, strengthening waste management during the production process is also an important means to reduce carbon footprint. By rationally classifying, collecting and treating waste, pollution and damage to the environment can be reduced. At the same time, encouraging and supporting the reuse and recycling of waste is also an effective way to achieve resource conservation and environmental protection.

In summary, the production process of integral welded flower pot has a certain impact on the environment, but by optimizing the welding process, selecting environmentally friendly materials and strengthening waste management, we can effectively reduce its carbon footprint and achieve a more environmentally friendly and sustainable production method.

In the production process of integral welded flower pot, welding is a key link. However, welding operations are often accompanied by the emission of harmful gases, such as ozone, nitrogen oxides, etc., which pollute the atmospheric environment. At the same time, the waste slag and smoke generated during welding also pose a potential threat to soil and water bodies. In addition, energy consumption in the production process, especially the use of electricity and gas, also exacerbates greenhouse gas emissions.

In order to reduce the carbon footprint in the production process of integral welded flower pot, we can take a series of measures. First, optimize the welding process, improve welding efficiency, and reduce energy consumption and harmful gas emissions. For example, the use of advanced welding equipment and technologies, such as automated welding robots, can significantly improve welding accuracy and efficiency, while reducing errors and pollution caused by human operations.

Secondly, choosing environmentally friendly materials is also the key to reducing carbon footprint. In the production of flower pots, priority should be given to the use of recyclable, degradable or low environmental impact materials. These materials not only have less impact on the environment during the production process, but are also easier to handle and recycle after being discarded.

In addition, strengthening waste management during the production process is also an important means to reduce carbon footprint. By rationally classifying, collecting and treating waste, pollution and damage to the environment can be reduced. At the same time, encouraging and supporting the reuse and recycling of waste is also an effective way to achieve resource conservation and environmental protection.

In summary, the production process of integral welded flower pot has a certain impact on the environment, but by optimizing the welding process, selecting environmentally friendly materials and strengthening waste management, we can effectively reduce its carbon footprint and achieve a more environmentally friendly and sustainable production method.